Sips,Structural Insulated Panels,Icfs, Insulated Concrtet Forms,Built Green

Built Green,Sustainable Structures,Energy Efricient Homes,Energy Star

Building Green with Structural Insulated Panels

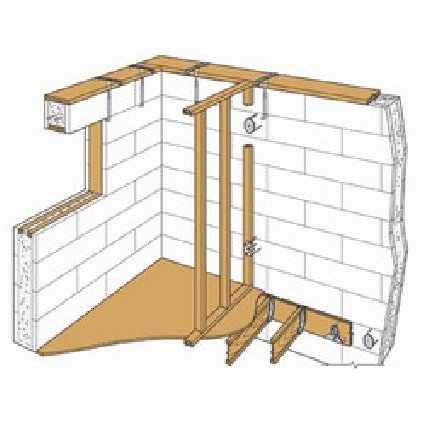

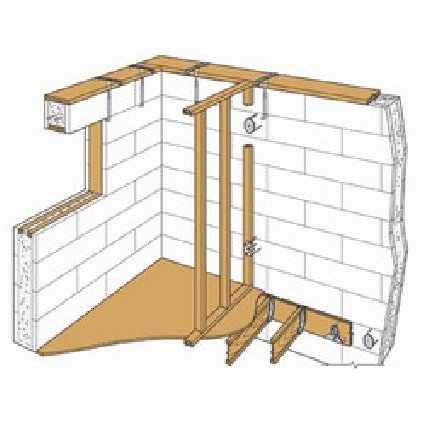

We have used many systems on various projects and have found the best and easiest to work with is the vertical system.

The vertical system has been engineered to solve the common problems of horizontal ICF design. The vertical orientation

eliminates the possibility of wall form floating and settling. It is dimensionally more accurate and can be easily made

to any height. The vertical system components form the walls, provide insulation, create a vapor barrier and serves as a

convenient and predictable attachment points. All this is accomplished in one step.

The vertical system is comprised of four main components:

1. Panels: made of 2.5-inch, high-density (1.95 pcf min.) rigid polystyrene

2. Corner sets: made of 2.5-inch, high-density (1.95 pcf min.) rigid polystyrene

3. I-beams: available in two materials

a) (Standard) rigid, recycled PVC

b) (Custom) double thickness 26-gauge galvanized steel

4. C-channel: 27-gauge galvanized and painted steel

Energy Efficient: Walls that provide an energy efficient (R-25 up to R-40) thermal barrier with a thermal mass

benefit results in reduced heating costs and cooling costs. ICF walls are used both below and above

grade.

Environmentally Friendly: Forms incorporate recycled materials, reduce the strain on our forests and reduce our

energy requirements through efficiency.

Soundproof: The density of concrete combined with the insulating properties of EPS result in extremely

quiet and comfortable structures. Indoor air quality can be greatly controlled in structures using ICF

building systems which helps increase the level of comfort.

Whether you're building a crawl space foundation, full basement or full wall structure out of concrete, Insulated

Concrete Forms (ICFs) are another energy efficient solution.

ICFs are a concrete forming system that allows builders to set the forms, pour the concrete and have a

fully insulated product. The forming system uses EPS foam planks or blocks set on footings. They

are assembled to the plans specifications for all dimensions. As with any foundation placement, walls

need to be plumb and dimensions accurate. The foundation needs to be level and square. If this beginning

for the structure is not accurate then the rest of construction will have difficulty. They usually have a

specified re-bar schedule inserted and then braced in place. Once they are ready they are then filled with

concrete. Finished ICF walls can receive wide varieties of interior and exterior finishes. The system

has attachment features with rigid PVC (recycled materials), or double thickness 26-gauge galvanized steel.

Another attachment option is fastening through insulation and into concrete.

Research Building Green... . More Information or comments e-mail

ICF's -Vertical System or Horizontal

Benefits of ICF Construction

What are ICFs?

Our Construction Information for Construction of High Energy Efficiency and Sustainable Structures

A building green web site sponsered by Build Green Companies

Green Building Information from BuiltGreenCo.com